Integrated Yarn & Fabric Preparation Unit

This unit focuses on advanced yarn processing and fabric preparation, ensuring optimal performance during weaving. To achieve superior yarn strength, uniformity, and readiness for high-speed weaving operations.

Our Airjet Looms are designed for high-speed, high-efficiency fabric production with exceptional consistency. Using controlled air pressure, we achieve precise weft insertion, ensuring uniform fabric structure across large volumes. This technology allows us to produce smooth, defect-free fabrics with superior surface finish. Airjet weaving supports tighter construction and higher productivity without compromising quality. It is especially suited for fine viscose fabrics requiring speed, stability, and repeatability. Automated controls enable real-time monitoring and quick adjustments. The result is reliable output with minimal variation from batch to batch.

Rapier Looms provide flexibility and control for weaving complex and diverse fabric structures. Their positive weft insertion system ensures accurate yarn placement, even for delicate or specialty yarns. This allows us to produce fabrics with intricate designs, varied textures, and consistent edge quality. Rapier technology supports a wide range of yarn counts and constructions, making it ideal for customized and value-added fabrics. The controlled weaving process reduces yarn stress and breakage. This ensures better fabric strength and long-term performance. Rapier looms balance precision with versatility in our production ecosystem.

Sizing is a critical preparatory process that enhances yarn strength and weaving efficiency. Our sizing systems apply uniform coatings that improve abrasion resistance and reduce yarn breakage during high-speed weaving. Precise control over size pickup ensures consistency across warp beams. This results in smoother loom performance and improved fabric quality. Proper sizing also contributes to better fabric handle and reduced defects. The process is optimized for viscose yarn characteristics. Consistent sizing directly supports productivity and fabric reliability.

TFO machines are used to impart controlled twist to yarns, improving strength, uniformity, and appearance. This process enhances yarn cohesion, making it more stable during subsequent weaving operations. Two-for-One twisting ensures consistent twist levels across the entire yarn length. TFO twisting is especially important for producing high-performance and decorative yarns. The process supports both functional and aesthetic fabric requirements. Reliable twisting contributes to overall fabric durability and consistency.

Warping is the foundation of accurate and efficient weaving. Our warping systems ensure precise yarn alignment, equal tension, and uniform beam formation. This consistency is essential for smooth loom operation and high-quality fabric output. Controlled warping minimizes yarn stress and prevents weaving faults. Each warp beam is prepared to exact specifications for the intended fabric structure. Proper warping enhances production efficiency and reduces downtime. It plays a vital role in maintaining fabric dimensional stability and quality.

Airjet Looms

Our Airjet Looms are designed for high-speed, high-efficiency fabric production with exceptional consistency. Using controlled air pressure, we achieve precise weft insertion, ensuring uniform fabric structure across large volumes. This technology allows us to produce smooth, defect-free fabrics with superior surface finish. Airjet weaving supports tighter construction and higher productivity without compromising quality. It is especially suited for fine viscose fabrics requiring speed, stability, and repeatability. Automated controls enable real-time monitoring and quick adjustments. The result is reliable output with minimal variation from batch to batch.

Rapier Looms

Rapier Looms provide flexibility and control for weaving complex and diverse fabric structures. Their positive weft insertion system ensures accurate yarn placement, even for delicate or specialty yarns. This allows us to produce fabrics with intricate designs, varied textures, and consistent edge quality. Rapier technology supports a wide range of yarn counts and constructions, making it ideal for customized and value-added fabrics. The controlled weaving process reduces yarn stress and breakage. This ensures better fabric strength and long-term performance. Rapier looms balance precision with versatility in our production ecosystem.

Sizing

Sizing is a critical preparatory process that enhances yarn strength and weaving efficiency. Our sizing systems apply uniform coatings that improve abrasion resistance and reduce yarn breakage during high-speed weaving. Precise control over size pickup ensures consistency across warp beams. This results in smoother loom performance and improved fabric quality. Proper sizing also contributes to better fabric handle and reduced defects. The process is optimized for viscose yarn characteristics. Consistent sizing directly supports productivity and fabric reliability.

TFO (Two-for-One Twisting)

TFO machines are used to impart controlled twist to yarns, improving strength, uniformity, and appearance. This process enhances yarn cohesion, making it more stable during subsequent weaving operations. Two-for-One twisting ensures consistent twist levels across the entire yarn length. TFO twisting is especially important for producing high-performance and decorative yarns. The process supports both functional and aesthetic fabric requirements. Reliable twisting contributes to overall fabric durability and consistency.

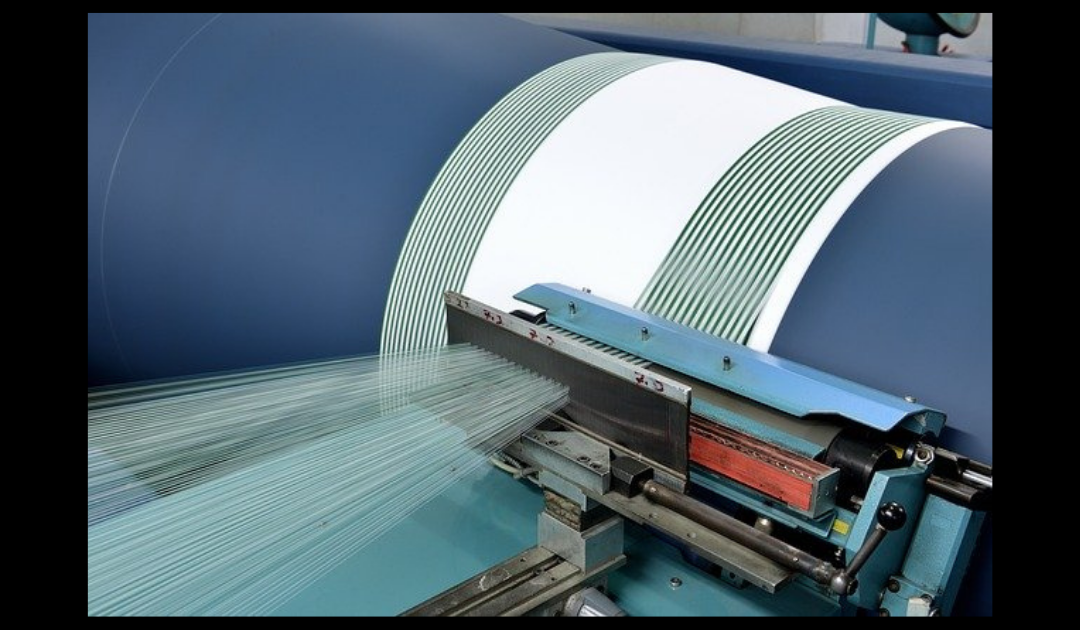

Warping

Warping is the foundation of accurate and efficient weaving. Our warping systems ensure precise yarn alignment, equal tension, and uniform beam formation. This consistency is essential for smooth loom operation and high-quality fabric output. Controlled warping minimizes yarn stress and prevents weaving faults. Each warp beam is prepared to exact specifications for the intended fabric structure. Proper warping enhances production efficiency and reduces downtime. It plays a vital role in maintaining fabric dimensional stability and quality.

Integrated Yarn & Fabric Preparation Unit

This unit focuses on advanced yarn processing and fabric preparation, ensuring optimal performance during weaving. To achieve superior yarn strength, uniformity, and readiness for high-speed weaving operations.

Airjet Looms

Every commitment is grounded in production capability and process discipline.

Rapier Looms

We focus on sustainable relationships rather than short-term gains.

Sizing

Clear communication, ethical conduct, and accountability across the value chain.

TFO (Two-for-One Twisting)

Clear communication, ethical conduct, and accountability across the value chain.

Warping

Clear communication, ethical conduct, and accountability across the value chain.

Yarn Go down & Handling Unit

This unit manages the storage, movement, and systematic handling of yarn to maintain quality and traceability. To ensure safe storage, minimal handling loss, and smooth supply flow across production units.

Dedicated Yarn Godown

To ensure safe storage, minimal handling loss, and smooth supply flow across production units.

Scientific Storage Systems

To ensure safe storage, minimal handling loss, and smooth supply flow across production units.

Efficient Yarn Handling & Inventory Management

To ensure safe storage, minimal handling loss, and smooth supply flow across production units.

Powerloom Manufacturing Unit

This unit is dedicated to fabric weaving using powerloom technology, supporting flexibility across fabric categories. To deliver reliable fabric output for diverse applications with consistent quality.

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Powerlooms

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Controlled Production Planning

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Fabric Inspection & Monitoring

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

This unit is dedicated to fabric weaving using powerloom technology, supporting flexibility across fabric categories. To deliver reliable fabric output for diverse applications with consistent quality.

Powerloom Manufacturing Unit

Powerlooms

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Controlled Production Planning

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

Fabric Inspection & Monitoring

Powerlooms are mechanized weaving machines that increase textile production efficiency, consistency, speed, fabric quality, and industrial-scale manufacturing capabilities.

This unit integrates high-speed weaving with specialized processes to enhance fabric value and versatility. To produce differentiated viscose fabrics with enhanced design, strength, and performance characteristics.

Advanced Weaving & Value Addition Unit

Airjet Looms

Warping

TFO (Two-for-One Twisting)

Jari Machines

A new unit currently under development, aligned with our long-term vision of growth, innovation, and capacity expansion. To further strengthen our integrated viscose ecosystem and meet evolving market demands.

Future Expansion

Coming Soon

Coming Soon

Together, these business units function as a unified ecosystem—enabling Reaghan Fashions to deliver quality, consistency, and scale across the viscose textile industry.